Deep dive on Circularity Regeneration.

Whether a decomposing plant returning nutrients to the soil or a fire-charred tree dropping seeds to regrow the scorched earth — regeneration occurs in nature every day.

This natural phenomenon of regeneration brings us to the third and final step of the circularity process — REGENERATE. Effectively, the regenerate step means turning or transforming waste into new resources, and the circularity process can begin anew to create new value. For example, food and animal waste can be converted into biomass which is a sustainable energy source, replacing fossil fuels. There are many other examples.

The Innovations Driving Regeneration

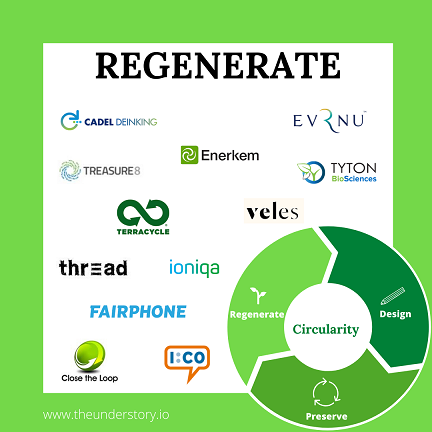

Who is innovating in the regenerate stage of circularity? Certainly, both material science and technology firms take center stage. Many organizations are finding novel ways to convert waste, especially working with materials or products, that previously could not be recycled into new resources. Let’s dive into this market.

Plastics

Only 9% of plastics are currently recycled and the remaining take more than 400 years to degrade in landfills¹. This is a mindblowing figure. Many companies are trying to figure out how to turn plastic into better use. Specifically, to reduce the amount of plastic that ends up in trash, companies are finding ways to make it easier to recycle plastics and transform them into new materials and products.

Ioniqa, for example, is able to recycle all colors of polyethylene terephthalate (PET) plastic — something that was never possible prior to their innovation. They found a way to dissolve PET plastic so that it can be harvested and produce new, clear PET products that are food safe. The company closes the loop for plastics and is a great example of circularity regeneration.

Another company enabling the regeneration of plastics is Cadel Deinking. The company has created an innovative technique to remove ink from plastics before they are recycled, which is important because ink spoils recycled products from a color and mechanical property perspective. Ink removal of used plastic expands potential uses of the same plastic. The result is a recycled plastic product that is as high quality as brand new plastic.

Textiles

Over 11 billion pounds of textile waste ends up in U.S. landfills each year, as only 15% of textiles are recycled². Innovators in circularity are finding ways to make it easier to regenerate quality textiles that can replace new materials. These recycling processes also contribute to a significant reduction in water usage since textile production uses a substantial amount of water.

Evrnu is a textile company that recycles discarded clothing, transforming clothes into an engineered fiber called NuCycl. The technology extends the useful life of the fiber by extracting its molecular building blocks and regenerating pristine new fibers which can be used multiple times. Textile waste becomes a thing of the past with Evrnu.

Another company in textile recycling is Tyton Biosciences. Tyton is able to recycle multiple types of textiles, including cotton, polyester, and poly-cotton blends. The company can produce new materials that are similar in cost and quality to virgin materials, making substitution a no-brainer for apparel companies.

Food Waste

U.S. consumers throw away over 38 million tons of food every year and almost all of it (94%) ends up either in landfills or combustion facilities³. Organizations are making it easier to compost and reuse what is leftover in novel ways, oftentimes converting the organic compounds to completely new raw materials.

Veles created an organic household cleaner that is made from food waste. The company invented a process to isolate the organic compounds and water from the waste and turn them into common chemicals and ingredients needed for cleaning. The innovation simplifies the supply chain by cutting out unneeded vendors and reduces the amount of harmful chemicals produced globally.

Treasure8 is also using food waste to regenerate new resources. They invented a proprietary process for dehydration which they provide in an as-a-service model, making it easier and more flexible for their customers to adopt. The company also uses its own process to generate new ingredients as well as full products that are sold to consumers.

Closing the Loop — Ideas for implementing regeneration for your organization

As your organization seeks to create new value across the circularity lifecycle, consider the following guidelines for implementing regeneration at scale.

- Increase waste awareness — Many organizations don’t know or care what happens to their products once those products are disposed as waste. With innovation in circularity solutions, organizations can and should ask questions to understand what type of waste and waste components are created by your business and supply chain. Knowing the waste materials on hand can inform how they can be used for regeneration and potentially long-term value creation.

- Seek vendors or partnerships — Regeneration often requires specific technologies or material science innovation and processes to convert waste to a new material. If regeneration is not your organization’s core strength, consider working with other companies that can facilitate the process for you.

- Create loops of value — Consider new ways to capture value across the circularity process. Can you monetize your waste by selling it to a partner that will recycle it? Can you purchase recycled materials to use as inputs to your own products? Reconsider how your role can morph and vary across the entire value chain.

- Organizational capability — Create a collaborative infrastructure that allows the sustainability team to work with the supply chain, technology and finance teams to ideate and form plans around possibilities of regeneration for the organization.

The economic model of the future is circular — use waste to regenerate new value and continue the ongoing circularity process.

[1] National Geographic. “A whopping 91% of plastics isn’t recycled”. December 20, 2018

[2] EPA. “Textiles: Material-Specific Data”. 2017

[3] EPA. “Reducing Wasted Food at Home”. 2017

Join the conversation.