Mycocycle transforms waste into new building materials through the process of mycelium-based bioremediation.

How does the waste management industry actually manage waste? You would think that an industry that is worth $993 Billion in 2022 and projected to grow to $1.7 trillion by 20301, would safely dispose of waste, or bring it back into the economy. Unfortunately, most of our refuse ends up being burned or buried underground. Mismanaged waste accounts for more than 400,000 deaths per year and negatively impacts the environment and surrounding communities. What would be appropriate to combat the current unsafe and inefficient waste management that is currently within our society?

Mycocycle has an innovative solution to deal with part of the waste issue - use nature as intended! In the natural environment, fungi (i.e, mushrooms) decompose waste. By utilizing the process of bioremediation, Mycocycle uses the natural properties of fungi to decompose industrial waste, remove harmful toxins from the waste, and turn it into a new product.

How does Mycocycle do this?

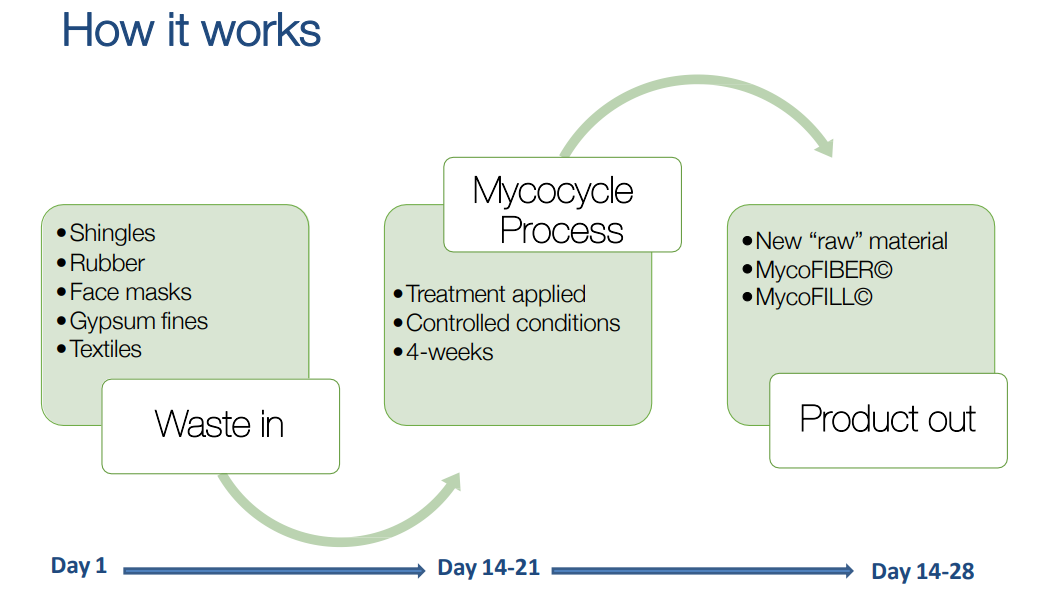

Mycocycle created a process that turns harmful waste into safe products that can be used in the built environment. Mycelium is the ‘root structure’ of a mushroom, and this is what is used to metabolize heavy hydrocarbons into safe, usable products. This is beneficial for diverting hazardous wastes that are facing regulatory issues regarding their disposal. Mycocycle starts all cultures in labs, and by staying current with research on mycoremediation, it ensures that any waste product can be effectively remediated. To date, Mycocycle has trained mycelium to consume fuel, plastics, rubbers, textiles, and many other manufactured products.

It all begins with a pre-treatment that is applied to the hazardous product to turn it into a viable substrate. After this, the substrate is ‘seeded’ with Mycocycle’s mycelium and takes a trip to a growth chamber for around 4 weeks. After this time is up, all of the toxins have been removed from the substrate, and the reusable byproducts are gathered to be transformed into another material.The recycled raw materials that Mycocycle produces are called mycoFIBER and mycoFILL. mycoFIBER is a wood substitute and mycoFILL is a calcium carbonate substitute, both of which can be used as raw material in the built environment. By regenerating materials, fewer raw materials are removed from the earth which also mitigates emissions caused by new material generation. Mycocycle has created flooring, tiles, and many other composites for the built environment.

Mycocycle works with material manufacturing, chemical manufacturing, recycling, and waste management to treat and divert waste while simultaneously generating new materials. Over the next 5 years, Mycocycle aspires to remediate and divert 5 million tons of waste.

Mycocyle is a great example of the last phase of the circular economy - regeneration. The company regenerates waste into new materials to close the loop on the process for these materials. Inspired by nature, innovations like this will help transform our economy from a linear to a circular approach.

To learn more about Mycocycle, watch Understory’s Startups Driving Sustainability - October 2021 Showcase or Understory’s Startups Driving Sustainability - April 2022 Showcase.

You can also listen to Joanne Rodriguez of Mycocycle on The Understory Podcast here.

[1] Precedence Research. Waste Management Market Size to Worth Around USD 1782.5 Bn by 2030. August 3, 2022.

Join the conversation.